Overview

Monel belongs to Ni-Cu family of nickel-based corrosion-resistant alloy. With composition of 70% Ni and 30% Cu, Monel has the widest application among all nickel-based corrosion-resistant alloys. It was first developed by International Nickel Co., Ltd.

Monel alloy features high strength and toughness, as well as excellent resistance to reducing acid, strong alkali medium and seawater. Therefore, it is commonly used for the equipment of hydrofluoric acid (HF), brine, neutral medium, alkali salt, and reducing acid media.

Introduction of Forged Monel

Monel alloys are available in both forged alloy and deformed alloy (rolled material). In terms of forged Monel alloy, ASTM A494 standard lists five grades, i.e., M35-1, M35-2, M-30H, M-25S and M-30C as Table 1; There are also five cast Monel alloys in the US Federal Standard QQ-N-288 as Table 2.

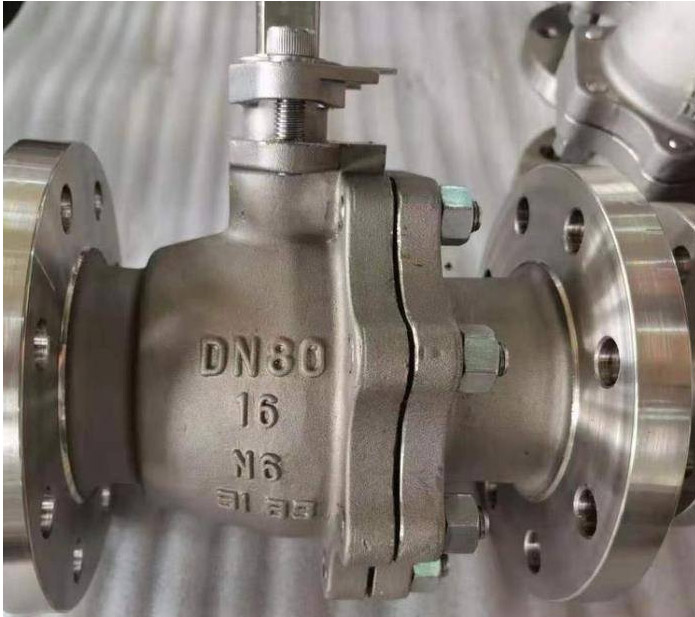

Selection of Monel Alloys for Corrosion Resistant Valves

M35-1, M35-2, and Classes A and E in QQ-N-288 are commonly used to make refined Monel alloy pumps, valves, and accessories. Class B Monel alloys featuring high Si (3.5 %Si) are mainly used to manufacture shafts and wear rings that require good wear resistance due to their high strength and resistance to corrosion and wear. Class D Monel alloys containing 4.0 % Si are used to make parts that require higher wear resistance and corrosion resistance.

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: